The Emerging Force In GET Systems

Parts Lookup

1300 363 969

Login

register

or

Here

Dozer

Fortus aims to set the standard in performance and reliability with a comprehensive range of GET solutions in mining, quarrying and construction applications.

System Overview

The dozer is a critical piece of equipment on mine sites across Australia. Used for ripping, pushing, stockpiling and levelling dirt, an efficient dozer operation strategy can directly affect the loading and hauling equipment for working more effectively by keeping blasting, loading, and dump areas clean.

Fortus supplies GET solutions for all dozer models. Fortus dozer GET solutions have been field tested in harsh and demanding Australian mining conditions and have been proven to improve the production and performance of dozers.

Through our close relationships and ongoing diversified strategic foundry partnerships and internal engineering team, we’re continually developing, designing & testing our parts to provide customers with the most innovative and cutting-edge GET solutions in a range of applications.

Our goal is to help you, our customer to decrease machine downtime and reduce cost per hour, extend maintenance wear life, and improve your machine productivity.

Cutting Blades and End Bits

End Bit Styles

FD – Finishing Dozing

Corner protection for normal to abrasive conditions, used when face wear is common.

UT – Utility

Used in low impact, low abrasion conditions, provides cutting depth equal to the cutting blades.

GD – General Duty

commonly used for general earthmoving and dozing applications. Has a thicker wear area for reinforced penetration.

EWL – Extra Wear Life

Used in abrasive conditions and for high production leveling, provides a thicker wear area and maximum cutting depth.

TCO – Tungsten Carbide Overlay

Used in extremely abrasive conditions to maximize productivity to the dozing application, adding an additional effective protection layer to drastically improve wear life.

Cutting Blade Duty Options

| Duty Description | Duty Detail | Illustration |

|---|---|---|

|

Standard Blades |

|

|

|

Heavy Duty Blades |

|

|

|

TCO Hard-Faced Blades |

|

|

Weld-on Wear Protection

Grouser Bars

Commonly welded on the track plates of machines, and also used in the screening and crushing environment as grid bars, they can also be used above the cutting blade or on the side of the blade attachment to provide protection to critical wear points.

Wear Bars/Strips

Wear strips allow agility of replacement to only a certain section where needed, making them easier and safer for installation. Wear strips are set to be easier to measure up, you do not have to measure radii and get the outside shape perfect like you do with a custom wear liner. The standard wear strips size can be found in stock with various suppliers.

Wear Liners

Wear liners are designed to minimize the amount of welding, and more thoroughly cover the parent metal. However, due to the dangers of dealing with stored energy in curved wear lines, more and more companies are going away from this method. Wear liners are more aesthetically appealing than a wear strip setup so attachment designers often prefer to install these to make their products look great. Fortus and other attachment manufacturers are innovating sectioned rolled wear liners that eliminate the risk of stored energy but provide most of the benefits of standard wear liners, and arguably better as they can be replaced section by section.

Ripper Shank

Fortus ripper shanks are designed to fit a wide range of mining dozers and have been manufactured using quenched and tempered wear plates. This manufacturing process ensures that each shank has a grain structure that provides improved structural integrity and wear resistance.

Fitment Range: CAT dozers D6 – D11, Komatsu dozers D275- D475.

Manufactured in Italy and Australia using quality European 400BHN quenched and tempered wear plates. Easy fitment, Despite the brand of ripper protectors or points.

Winged Tyne

What is its purpose?

The Winged Ripper tyne is used in rehabilitation projects, for relieving compaction in the ground to help seedlings of native trees germinate. The wide wings lift the soil and relieve compaction in the old pit floor being rehabilitated, the pit floor becomes compacted after months and years of heavy equipment driving over it making it difficult for flora to flourish at the end of pit life.

After using the winged tyne the typical practice is to do contour ripping with a multi-shank ripper to create furrows that stop water from running off. Then rich topsoil is spread over the area so seedlings have the nutrients and support needed for life.

Machine applications?

Initially designed for D11, Fortus can custom design for smaller dozers.

Where are they made?

Designed, engineered, and manufactured in Australia.

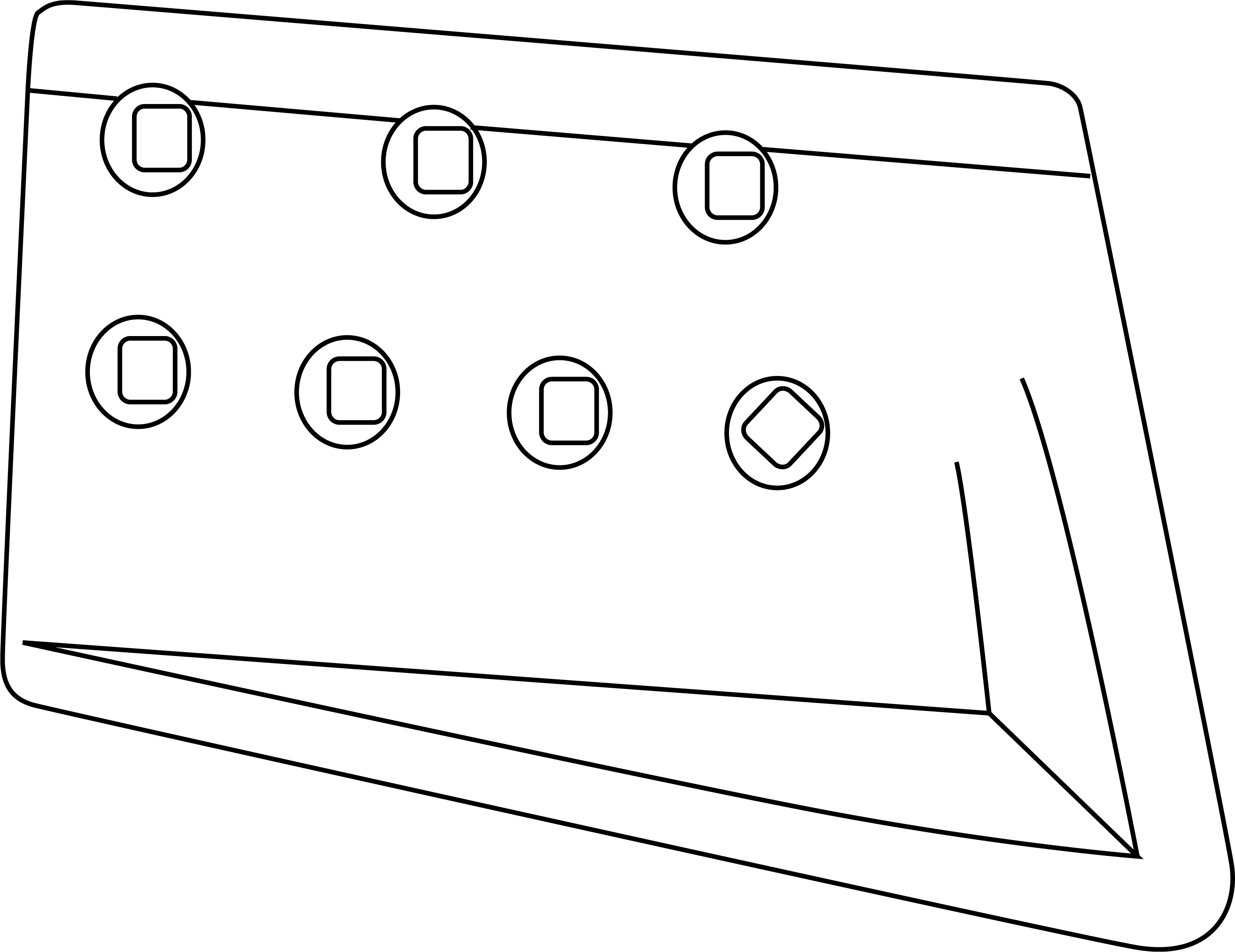

Ripper Shank Protection

Shank protectors help protect the shank, it cuts through material with sharp edges and protects the shank above the boot which is a high-wear area.

Having trouble finding the right part?

Our parts identification systems make it easy to find the parts you need when you need them. If you can't find what you're looking for, don't hesitate to contact us. Call us or fill out the enquiry form now, and our team of parts specialists will help you find the correct part to meet your needs.